Poor Quality Control and Outdated Equipment at Steel Company Behind Failed Gears on Ill-Fated CV-22 Osprey

The CV-22B Osprey crashed following a catastrophic failure in the left-hand Prop Rotor Gear Box, triggered by a crack in one of the high-speed pinion gears manufactured from a special steel alloy produced by Universal Stainless.

An independent investigation by Hunterbrook has narrowed down poor manufacturing processes and inadequate quality control as the causes of the catastrophic failure in the Prop Rotor Gear Box (PRGB), which led to the crash of a U.S. Air Force CV-22B Osprey on Nov. 29, 2023, off the coast of Japan, resulting in the deaths of eight personnel. These issues were traced back to Universal Stainless, the manufacturer of the alloy used in the gear that failed on the ill-fated Osprey.

Hunterbrook’s investigation, which followed both the Accident Investigation Board (AIB) and the internal Safety Investigation Board (SIB) reports, found a troubling mix of “toxic” personnel management and “retaliatory” practices at the manufacturing site. These factors compromised the rigorous standards essential for aerospace components, favoring increased production volumes and “high profit margins” instead.

Previous accidents involving the Osprey were attributed to a recurring “hard clutch engagement,” a result of a design flaw in the component. However, in the November 2023 crash, investigators pointed to the gearbox as the cause in their preliminary findings. At that time, while they had established the “what” of the failure, they were still probing the “how” and “why.” The specific gear that failed was manufactured using a special steel alloy supplied by Universal Stainless.

BREAKING: Universal Stainless and Alloy Products (NASDAQ:$USAP) is reportedly behind the deadly crash of a USAF Osprey in Japan last year.@hntrbrkmedia found glaring issues in Universal’s operation, which supplies steel to major aircraft manufacturers including Boeing. pic.twitter.com/9arbZTrO2u

— OSINTtechnical (@Osinttechnical) October 23, 2024

What is shocking, and bares the larger scale of the impropriety, is that Universal’s specialty steel alloys figure across the entire U.S. aviation sector, including its major customer Boeing, aircraft engines, and possibly the V-280 Valor, part of the U.S. Army’s FLRAA (Future Long-Range Assault Aircraft).

The crash of the Osprey claimed the lives of Maj. Jeffrey T. Hoernemann; Maj. Eric V. Spendlove; Maj. Luke A. Unrath; Capt. Terrell K. Brayman; Tech. Sgt. Zachary E. Lavoy; Staff Sgt. Jake M. Turnage; Senior Airman Brian K. Johnson; and Staff Sgt. Jake Galliher.

What caused the November 2023 Osprey crash?

The USAF CV-22B Osprey (callsign Gundam 22) from the 21st Special Operations Squadron, 353rd Special Operations Wing at Yokota Air Base, crashed off the Japanese coast on Nov. 29, 2023, after taking off from Marine Corps Air Station (MCAS) Iwakuni, while participating in a joint interoperability exercise.

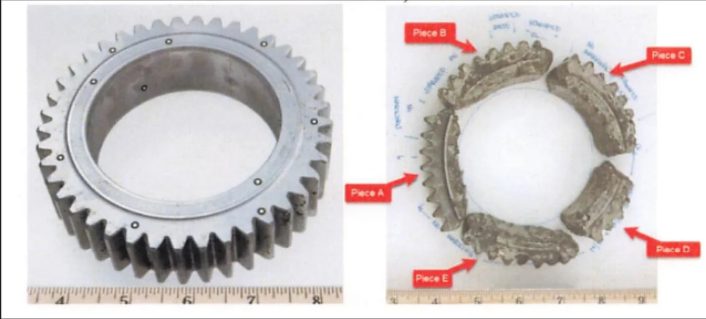

The tilt-rotor CV-22 has a prop-rotor gearbox in each engine nacelle which transmits power from the engine to the proprotor and reduces the speed of the shaft. The catastrophic failure was located in the Osprey’s left-hand PRGB. Here is an excerpt from the AIB report:

“Failure of the left-hand PRGB high-speed planetary section was most likely initiated by a crack in one of the high-speed pinion gear and fatigue cracking of the associated pinion gear’s bearing cage, which eventually fractured through the high-speed planetary carrier assembly. At least one piece of the failed high-speed planetary pinion wedged in the high-speed carrier assembly, grinding against the high-speed sun gear’s teeth until they were completely removed. The removal of the gear teeth prevented torque being applied to the left-hand mast”.

The report then mentions that an onset of rapidly cascading malfunctions occurred less than six seconds after the failure. This resulting “instantaneous asymmetric lift condition” was unrecoverable by the mishap crew. The crew received three “PRGB CHIP BURN” alerts on the CDU screen, followed by a “L PRGB CHIPS” flash. This meant the chip detectors found pieces of metal that couldn’t be burnt off.

CV-22B Osprey 10-0055 as ” XXXXXX ” departing KCOS to go to Kirtland Air Force Base. pic.twitter.com/inBkcF6zTb

— 𝙎𝙍_𝙋𝙡𝙖𝙣𝙚𝙨𝙥𝙤𝙩𝙩𝙚𝙧 (@SR_Planespotter) December 7, 2022

While heading to Yakushima Island, the nearest planned divert airfield, and while waiting for traffic to clear the runway, a “CHIP DETECTOR FAIL” warning indicated one of the chip detectors completely stopped working. The pinion gear then completely failed, triggering the cascading series of malfunctions, causing the left proprotor to stop spinning. The Osprey went into a roll and crashed into the water.

‘Gear pinion manufactured by Universal Stainless failed’

The single ‘high-speed planetary gear pinion’, according to Military.com perusing the SIB report, had “begun to shred.” The resulting debris in the gearbox presumably triggered the alerts mentioned earlier, causing the crash. While both the publicly released AIB and the internal SIB blamed this single gear, the latter mentioned that the “single crack” was “similar to those seen on seven previous failures in low-speed planetary pinion gears.” Five of those prior failures, which go back to 2013, were caused by “non-metallic inclusions” – defects in the metal alloy from which the gears were made. Gundam 22’s gear also cracked “most likely due to non-metallic material inclusion.”

Universal Stainless made the alloy that “later failed in Gundam 22”. Since 2014, the company has supplied a “significant proportion” of the alloy used in the Osprey gearboxes that are now under scrutiny, Military.com said, quoting the SIB. Fortunately, however, the other incidents saw the aircrafts landing “before the gear failed completely.”

In 2014, the Osprey Joint Program Office received a risk assessment titled “Gear Metal Raw Material Impurities” from the aircraft’s manufacturers, Bell Textron and Boeing. But the SIB said the notice “did not adequately assess risk of high-speed gear failure.” There was also no testing of the high-speed gears done at the time, meaning there wasn’t an “adequate understanding of the failure that occurred in this mishap.”

NAVAIR (Naval Air Systems Command), under which the JPO falls, implemented contractual financial withholds, according to the SIB, hoping the contractor would “correct deficiencies in the (alloy) processing that had resulted in previous gear failures.” But this method “did not prompt corrective actions.”

‘Deficient manufacturing, poor quality control, toxic work culture’

Universal Stainless, a key supplier for Boeing – itself facing allegations of shoddy manufacturing standards amid a standoff with workers’ unions – has a history of quality control issues dating back to 2001. At the time the company was sued by Teledyne Technologies for defective steel that caused “multiple crankshaft failures” in aircraft engines, with “over 90% of the crankshafts found to be flawed.”

Former Universal Stainless employees describe a toxic workplace culture with equipment dating back to the 1950s, pressure to prioritize production over quality, “racial discrimination and unsafe working conditions.” Universal is now facing lawsuits from multiple former employees, for racial and age discrimination, disregard for safety, and retaliation against whistleblowing employees.

Hunterbrook’s study also carried an illustrative graphic from Aperam, a European steel company that is set to acquire Universal Stainless, which showed the latter’s alloys making up the components Boeing commercial aircraft, engines and the V-280 Valor. In Boeing aircraft, it includes landing gear, actuator/hydraulic systems, hinges and actuators and fasteners.

In commercial aircraft engines, Universal’s alloys are present in the casings, shafts, bearings and blades. In the V-280 Valor, they are present in the drive shafts, gears, bearings and structural components.

‘Inclusions’ industry-wide problems or Universal Stainless-specific?

There are “varying” views over whether the defects were unique to Universal’s products. Hunterbook quoted a podcast by Aviation Week Network, where its senior editors said that “the raw material supplier for the pinion gear that ultimately shattered and failed in this case used a process that creates a higher incidence of this nonmetallic inclusions.” The podcast then continued saying “other suppliers that supply the same type of material use a totally different process where the rate of that incidence of…(non-metallic) inclusion…is much less.”

However, The Air Current called inclusions an “insidious problem that has not been fully solved in either military or civil aviation.” For instance, Bell has been working with several alloy producers over the years, but inclusions were found in products from multiple manufacturers.

Possibly, the inclusions at a broader level could be a general technological problem requiring greater internal research and development by metal fabrication and forging companies. But considering former Universal Stainless employee Ryan Smith’s statements to Hunterbrook, who cited “outmoded equipment” used by Universal Stainless, makes it hard to absolve the company.

Hunterbrook cites the 2014 case of British aerospace major Rolls Royce, which discovered a “large air pocket” in the center of a steel bar produced by Universal. Smith told Hunterbook: “We got this bar back and the ends were great, but the middle of the bar had this massive air pocket in it. I don’t understand how you miss that.” He added that somehow the bar had been passed through about “10 departments.”

In this context, Smith said that the steel is “refined by an outdated facility” at Dunkirk in New York, unlike its “state-of-the-art” and “sophisticated” plant at North Jackson, Ohio. Some equipment “dates back to the 1950s” or even “the World War era”. “You can’t even get parts for this stuff.” Smith added. During his time at Universal Stainless, meetings addressed manufacturing only “after a customer discovered a problem, rather than through internal quality control.”